For support “World Environment Day June 5, 2009”

Have you imagine that one day in the future, land vehicles could not use on the road? Yes, it is possible and will be happened because all car companies in the world produce a number of cars every day whereas old cars which ages 30 years are still able to operate on the road. This issue will become a problem for government, producer, and also customer in every country in the future. On the other side, it can be a potential opportunity for automotive manufacturing company to invest an automotive recycling factory.

Moreover, end of life vehicles and unused vehicles occupy usually vast expanse of landfill. This condition will happen to degradation of environment because it is inclusive of hazardous waste (dangerous and poisonous). Actually, this waste is a potential energy if it could be reduce, reuse, recycle, and recovery (4R). Currently, 4R are implemented by unauthorized company or individual. But, it cannot 100% part of vehicle can be reduced, reuse, recycled, and recovered.

Investment in this business is not easy to implement because it processes waste that the world concern about. It needs carefully research about the impact of environment and also study of law or regulation. Moreover, it needs big investment but the revenue of this business will be also high. Today, the annual sales of an average ELV dismantler in Shanghai are about $2,784,503 and annual revenue is about $496,368. Assuming that the average level of operation and management of ELV dismantlers nationwide is similar to that of the dismantler in Shanghai, it is estimated that the annual sales of the national ELV dismantling industry are about $850-960 million and annual revenue about $169 million (Chen, 2005).

Where is the best place to build automotive recycling factory?

Huge land countries like China, United States, Canada, and Indonesia are contributed in vehicles consumption. For example, automotive factory in Indonesia could sell cars approximately 600,000 units in 2008. An opportunity to build automotive recycling factory in huge land country is very good. Beside the land is still available, natural resources and human resources are also easier to acquire.

If hand phone and gadget like Nokia can be recycled 100%, how about cars?

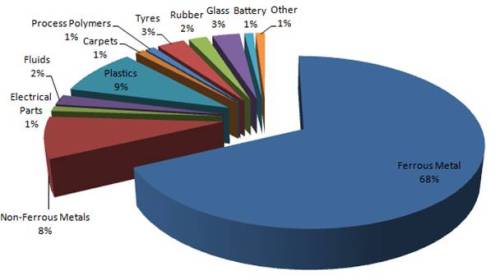

Car consists of many parts and materials. The breakdown materials by weight diagram below shows that metal are a dominant material (68% ferrous metal and 8% non-ferrous metal).

Source: ACORD, Annual Report, 2001

Metal (76%)

Metal dominates around 76% of a car weight. Currently, 98% of metal in a car are recovered by steel industry and re-smelting plants. One of good news is that automotive manufacturing companies historically redesign car with reducing the weight of metals in a car. This reducing can support eco labelling product and environmental friendly product because it can reduce the total weight of car. Hence, the consumption of fuel is also reduced.

Plastic and Polymers (10%)

Plastic and polymers contribute roughly 10% of a car weight. Car manufactures use plastics increasingly from 1980s until today. In addition, utilizing plastics in a car for changing metal is more environmental friendly. Besides low cost, using plastics can decrease weight that has impact in decreasing the consumption of fuel. Automotive usually use polypropylene (PP), polyethylene (PE), polyurethane (PU) and polyvinylchloride (PVC). PP is common use in bumpers, dashboards, engine component, interior trim moulding, and wheel arch liners. Then, PE and PU are common use in seat foam and seat belt. The rest of plastics parts are PVC.

PP, PE, and PU categorize plastics which are easily recycled. Plastic waste is chopped into flakes or pellets, and then it becomes the raw material of plastics. It can be melted into new product of plastics. In contrast, PVC is difficult to recycle. Alternative disposal method of PVC is incineration, but it related with environmental concerns. The emission during incineration is dioxin and phthalate plasticisers which are thought to be disruptions of hormone system. Currently, car manufactures are doing research to change PVC.

Tyre, Rubber, and Carpet (6%)

Tyre, rubber, and carpet obtain approximately 6% of a car weight. Number of options for reuse, recycling, and recovery are following.

-

Scrapped and vulcanized to reuse treys in good condition.

-

Tyre can be shredded and the rubber granulated for use in other products, sports surfaces, paints, flooring, etc.

-

Tyre can be recycled by cryogenic fragmentation. First, tyres are shredded and cooled to below -80°C. Then, The resultant rubber granules can be used for athletics tracks, carpet underlay, playground surfaces and rubberised asphalt for road surfaces.

-

Tyres are broken by microwave prototype into their original component. The steel is recoverable. The carbon and oil also can be reused.

-

Pyrolysis is heating tyres without air; then the gas, oil and carbon can be reprocessed. In big capacity, this process also produces energy that can provide electricity.

-

Tyre are incinerated to extract energy.

-

Tyre can be used as a fuel in the manufacture of cement. 25% of the coal, replaced up from tyre, can be used in cement kilns and reduce nitrogen oxide emission.

Glass (3%)

Glass possesses approximately 3% of vehicles weight. Two types of glass are common use in the automotive industry; toughened glass and laminated glass. Toughened glass is easy to remove from vehicles. Laminated glass need to be removed manually. It is crushed into cullet (small pieces) and melted, then moulded to make new product like bottle and jar. Majority, the most of glass waste are sent to landfill because the value of glass is relatively low to recover. Most of industries are not interesting in glass recycled because it is profitless.

Fluids (2%)

The problem of fluids like engine oil is not only for end of life vehicles but also for vehicles during service or maintenance. Wrong treatment to dispose fluids can pollute clean water. Three options of oil disposal are reuse, recovery, and recycle. First, oil can recover as mucky lubricant for simple use. Second, oil can be used as a fuel burnt in heavy industry and power stations. Third, oil can refine as clean/base lubricant for the raw material of lubricating oil. The first treatment is boiling oil to remove water and remove metal particles.

Battery (1%)

Currently, the recycling rate for car batteries is estimated to exceed 90%. If the electrical component like lead anode and cathode pole and the plastic case do not broken, battery can be used again with refilling acid and distilled water. Battery consists of 4 materials that can be recycled. First, plastic battery cases can be recycled to be raw material. Second, lead cathode and anode can be melted down to be raw material of lead. Third, acid can be treated and neutralized. Forth, distilled water can be purified and used again.

Electrical Parts (1%)

Electrical Parts relatively complicate to be recycled because it contains of many different type of parts. Two options can be chose to recycle electrical parts. First, the electrical component disposal can be sold back to the electrical part supplier to be repaired, reused or recycled. Second, electrical parts actually are assembled from raw material like plastics, metal, glass, rubber, and so on. Hence, it is recycled with breaking down the component and recycles separately based on the material.

Other Components (1%)

A car is supported by approximately 1% additional groups of components. It consists of leather, foam, cloth, and so on. Because of this component in a small portion of car, it can be more profitable if company sells back to the supplier to be reused or recycled.

Conclusion

Theoretically, almost 100% of end of life car can be recycled. Despite of investment to open new plant for vehicle recycle needs a lot of money, it is a potential business. Many benefits will be taken by companies if they invest in this business sector.

-

Opening vehicle recycling company needs many resources. Besides of land, investment, and material; man power resource is also needed. It means opening new vocations and decreasing unemployment.

-

Investing in vehicle recycling company can help environment healthier and supports environmental friendly movement. Opening vehicle recycling company means processing waste into new product or raw material. Hence, it can decrease pollution. If this company is opened by automotive company, it will be additional benefit; because customers will be more trust and loyal.

-

Special for automotive company, this company will give additional profit because it will be a supply cycle. Thus, the supply of raw material will come from both supplier and vehicle recycling company.

On the other hand, this business also has many difficulties. Opening vehicle recycling company is not easy. Many factors should be considered in this project like law and environment (pollution of air, water, and soil). To open this company needs deeply law studies because it related with processing waste. As people know, sometimes waste is very dangerous because it can be polluted environment. Moreover, to open a company needs big investment.

If I were to make a recycling plant, what should i do first?

What steps should I take to make my recycling plant works?

How much in land masses and Rp. am I looking at?

Hi Robert, thanks for comment. Actually, it is just an article that I made. But, it is nice to discuss.

I think that you can grow it from recycling one part to other parts until recycling a whole of car.

So, you should first know what part of car that you are interesting with and what part of car that you think profitable.

Recycling plant for whole part of car needs huge investment, but it is very profitable.